BP714 Earth Block Press Unique Double Compression

The BP714 Earth Block Press

The BP714 uses a unique double compression method that produces block strengths that exceed the compressive strength required for concrete block. The Blocks are 10 x 18 x 35.5 cm, and the machine produces 800-1400 blocks in 8 hours. The BP714 uses manually operated levers for filling the chamber, each stage of compression and ejecting the block. An experienced operator can reach 1400 blocks in 8 hours. It is recommended that the BP714 is sold as a complete system / success package, which includes a spare parts kit, a mixer, two weeks on-site training and a soil test kit.

$26,705 USD (with discounts available.)

For more flexible Block making options, Click Here

Ital Block PressBP714 How To Video

BP714 Technical Specs

Weight: 2800 lb (1270 kg)

Dimensions: 80.4” H X 100.1” L X 40.9” W (204.2 cm H X 254.3 cm L X 103.9 cm W)

Engine: Hatz 1D81Z single-cylinder, air-cooled diesel with manual start

Engine power: 12.6 hp (9.4 kW) at 2700 rpm

Hydraulics: Suction and return hydraulic filtration

Hopper capacity: 30 gal (4 ft3) [113.6 L (.1m3)] approx. 14 blocks

Normal block production: 3 blocks per minute.

Wall surface area: 0.388 ft2/block (0.036 m2/block)

Block dimensions: 4” H X 14” L X 7” W (10.2 cm H X 35.6 cm L X 17.8 cm W)

Weight: 20 lb (9.1 kg)

Block configurations: Flat top and bottom as well as interlocking profiled block plates available.

Fuel consumption: 3 gal (13.5 L) per 8 hr

Fuel tank size: 1.9 gal (7.2 L)

Recommended daily maintenance time: 10 min

Electrical system: None

Skid-mounted with fork truck access

Compression chamber: Unique dual-stage compression. Abrasion-resistant steel wear plates for added life. Quick change compression, top and bottom, plates for various profiled blocks.

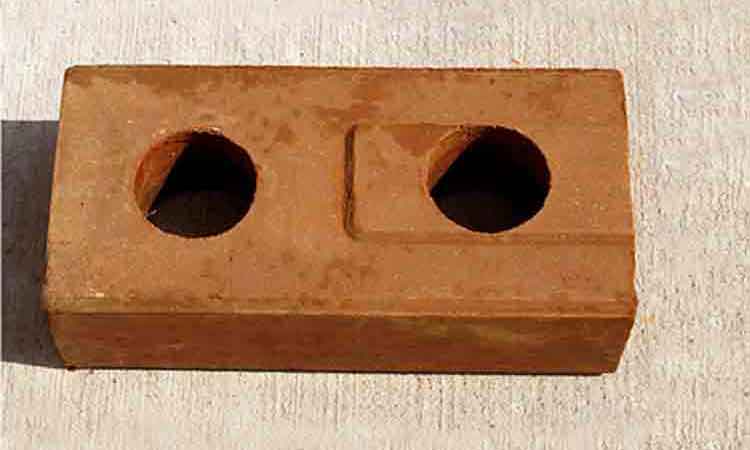

Blocks: Flat or interlocking block configurations. Dry-stacking for faster construction. Hollow cores for vertical reinforcement rods, filling with cement mortar and horizontal reinforcement cavity permitting use in designs for seismic zones.

One-third less soil needed for block configuration due to hollow cavities.

Strong linkage brackets

Measurement scales for mold chamber fill depth and block height adjustments

BP714

Why Build With Earth Blocks?

There are truly no restraints to the kind of homes you can build with Earth Block Construction. A compressed earth wall is resistant to sound transmission, fire and insect damage. With little maintenance a compressed earth wall can last for hundreds of years. The mass of the earth walls acts as an Energy storage system, helping to keep a house cool when it is hot outdoors and warm inside when it is cool. This reduces the need for heating and air conditioning.

Stronger Than Concrete

Compressed earth blocks are one of the most inexpensive building materials in the world. Including the cost of the equipment, maintenance and fuel, the cost of compressed blocks can be considerably less than other building methods when produced in volume.

Compressed earth blocks are all natural and the total energy required to produce them can be dramatically less than the energy required to make bricks or cement blocks. This makes compressed earth blocks among the most environmentally friendly material available today and conserves our natural resources.

Simplicity

The simplicity of the compressed earth building system allows the use of workers with little to no prior building experience thus reducing labor costs. The interlocking block design means building with much lower labor costs and building faster. The blocks can be dry stacked eliminating the major cost of mortar. When compared to other building systems, the overall costs have been from 5% to 40% lower using just the dirt beneath our feet.